+

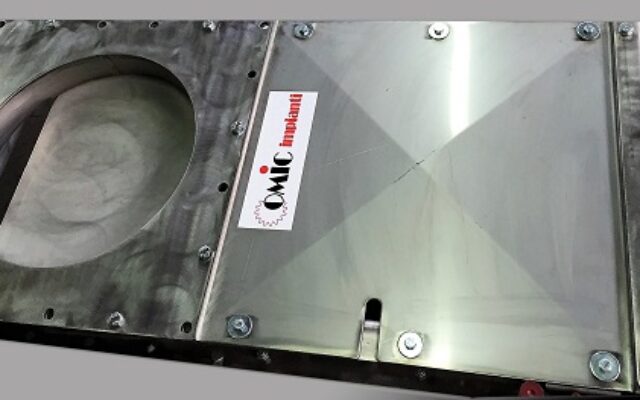

Guillotine Valve

The OMIC Knife Gate Valve is used where a bulk flow of material, caused either by gravity or transport, must be intercepted. It can be installed under the loading and unloading ports of mechanical conveyors or on the loading ports of telescopic unloaders. The OMIC Guillotine Valve consists of a two-piece frame that is partially lined with the technopolymer SINT and a blade lined with the same material, or entirely in stainless steel. The use of SINT considerably increases abrasion resistance compared to traditional type valves.

+

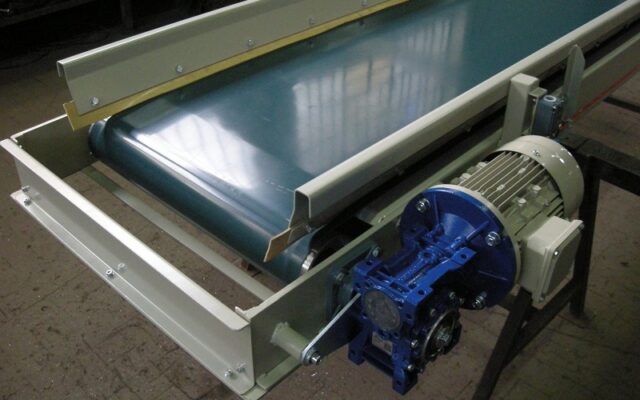

Conveyor belt

The OMIC conveyor belt is a machine for handling and transporting small grain size material, soils, clays or small to medium-sized individual packages on a horizontal or inclined plane. The general classification of OMIC conveyor belts is based on the type of frame (concave or flat) and motorisation (coaxial, pendulum, worm gear motor).

+

Elevator

The OMIC elevator is a machine designed for the vertical handling and transport of small grain size material, soils, clays or small to medium-sized individual packages by means of buckets rigidly fixed on a high-strength rubber mat for the belt model and on fixed chain buckets for the chain model. The general classification of OMIC elevators is based on the width of the belt and the capacity required by the plant.

+

Coclea

The OMIC screw conveyor is a machine designed to handle and transport atomised, impalpable powders with a maximum fineness of 15 mm horizontally or at an angle of not more than 35°. Its primary function is to extract materials from silos or storage hoppers.

+

Deviatore

The OMIC diverter is an automated machine consisting of a vertical cylinder, two ground chrome-plated rods, equipped with self-aligning supports that allows any material already processed to be discharged from a conveyor belt to a belt or hopper or silo below.

+

Vibrating screens

The OM10 screen (electronic head screen) has the function of separation and classification on all kinds of products, with the possibility of obtaining different separation cuts by inserting several nets at the same time. Screening effectiveness is guaranteed by the double action of the electronic heads:

- Intensity pulses

- Pulses of duration.

+

Feeder box

The OMIC feeder box is designed specifically for clays and material in general. It is supplied with support columns. The body has smooth inside walls with overhangs and profile reinforcements on the outside. Load cells for weighing can be attached.

+

Deferrifier

The iron remover type GMA-13 and GMA-15 OMIC purifies powders and is equipped with a 'NEODYMIUM 650 GAUSS' magnetic grid 15 bars D.25 arranged in 2 rows, AISI 304 stainless steel casing, 2 pneumatic cylinders, pressure reducer and electric control panel complete with timed system.

+

Star rotary extractor

The OMIC rotary extractor is used for the extraction of storage silos and powdered products with a medium moisture content. The star-shaped inner part is made of stainless steel to eliminate possible corrosion

+

Atomised colouring

The possibility of dry-colouring the spray-dried base enables products with infinite colour nuances to be obtained; the spray-dried base to be coloured is extracted by means of a weighing belt. The micro batchers make it impossible for material 'bridges' to form and allow for rapid cleaning. The special paddle dyers are equipped with an automatic cleaning system with full discharge opening. Dosing control software developed in cooperation with Infomotion srl.

*** Translated with www.DeepL.com/Translator (free version) ***

*** Translated with www.DeepL.com/Translator (free version) ***