+

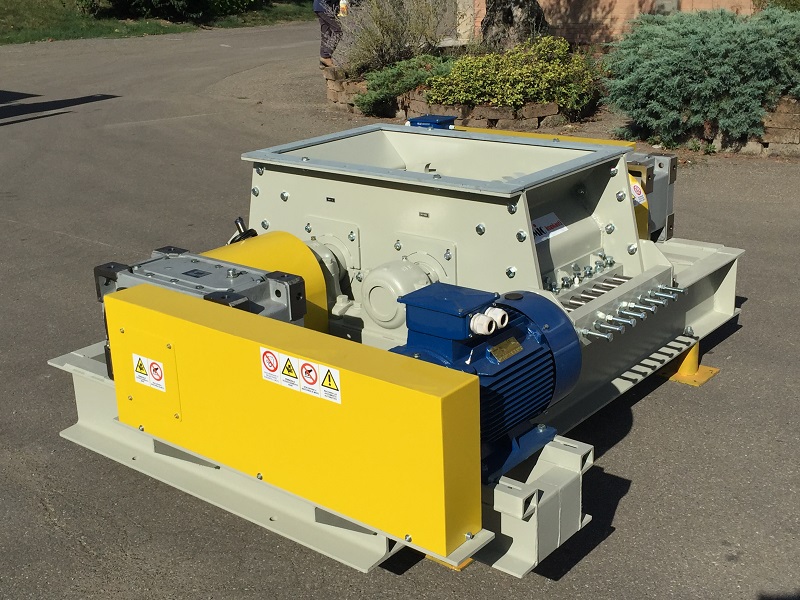

SM 500 SHREDDER

A technologically innovative system for processing very hard wet and dry clays. For the ceramic/material industry our comminution machine available in the SM300 / SM400 / SM500 models certainly represents evolution, for OMIC Impianti a source of pride for its commitment and passion. Essential machine for reducing clods from quarries so that they can be accepted by subsequent processing machines such as mills or rolling mills.

| Power | 45/37 Kw |

| Production | 120 Tons/h |

| Capacity | 100 m3 |

| Mass | 10,000 kg |

+

SHUTTER FEEDER BOX

The OMIC feeder box is designed specifically for clays and material in general. It is supplied with support columns. The body has smooth inside walls with overhangs and profile reinforcements on the outside. The pad is made of curved sheets to eliminate soil loss.

+

SM 400 SHREDDER

A technologically innovative system for processing very hard clays both wet and dry. For the ceramic/material industry our comminution machine available in the SM300 / SM400 / SM500 models certainly represents evolution, for OMIC Impianti a source of pride for its commitment and passion. An indispensable machine for reducing clods from quarries so that they can be accepted by subsequent processing machines such as mills or rolling mills

*** Translated with www.DeepL.com/Translator (free version) ***

*** Translated with www.DeepL.com/Translator (free version) ***

| Power | 45/37 Kw |

| Production | 120 Tons/h |

| Capacity | 100 m3 |

| Mass | 10,000 kg |

+

HERBERT ATRITOR pulveriser dryer mill

HERBERT POWDER DRYING MILLS are used to grind raw materials of varying nature, specific weight and moisture to medium hardness (clays, calcium carbonate, bentonite, gypsum, dolomite, etc.) with very high outputs and exceptional quantities of fine material.

+

ARO-TYPE ROTATING RING MILL

The Rotary Ring Mill type 'ARO' is particularly suitable for grinding abrasive or hard minerals. The special arrangement of the grinding rings allows high grinding fineness and low wear of the grinding parts. It is possible to adjust the tension of the springs and the speed of rotation of the ring to achieve predetermined grain size curves. The machine is made entirely of quality cast steel, while the shafts and roller bearings are oversized to give the assembly a long service life.